Unlocking Precision Engineering with wire edm production services

In today’s advanced manufacturing landscape, precision is not a luxury — it’s a necessity. Industries ranging from aerospace and automotive to medical devices and electronics require ultra-precise components made from hard-to-machine materials. This demand has led to the widespread adoption of wire edm production services, a specialized machining process that has revolutionized how parts with tight tolerances and intricate geometries are produced.

Wire Electrical Discharge Machining (EDM) may sound like a complex process, but its impact on modern fabrication is undeniable. wire edm production services provide unmatched accuracy, material versatility, and cost-efficiency — positioning them as a preferred solution for companies that need consistent quality at competitive prices.

What Are Wire EDM Production Services?

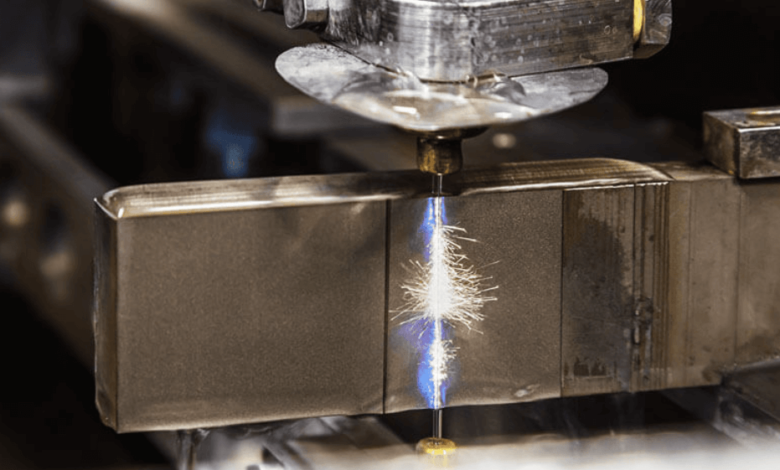

At its core, Wire EDM (Electrical Discharge Machining) is a non-traditional manufacturing method that uses a thin wire as an electrode to erode material from a conductive workpiece using electrical sparks. Unlike conventional cutting tools, wire EDM involves no physical contact, which eliminates mechanical stresses, deformation, and tool wear.

wire edm production services offer precision part manufacturing using this technique, especially for hard or delicate materials. These services cater to high-mix, low-volume to mass-production scenarios and are commonly used to fabricate dies, molds, prototypes, and critical components in sectors where dimensional accuracy is paramount.

See also: Advanced Graphics Technology Powers Sweet Bonanza’s Vibrant Visual Effects

Key Features of wire edm production services

1. Micron-Level Precision

Wire EDM is capable of producing parts with tolerances as tight as ±1 micron. This high level of accuracy is ideal for applications in medical implants, aerospace components, and electronic connectors where precision is critical.

2. No Mechanical Force

Since there is no direct contact between the wire and the workpiece, materials are not subjected to mechanical stress. This feature allows for the machining of thin walls and delicate structures without distortion.

3. Superior Surface Finish

wire edm production services provide surface finishes as fine as Ra 0.1 to Ra 0.4 micrometers. This eliminates the need for secondary polishing or grinding in many cases.

4. Complex Geometries

Wire EDM can create intricate shapes, sharp internal corners, and tight radii that would be difficult or impossible with conventional tools. It’s perfect for designing features like undercuts, small slots, or micro-holes.

5. Material Flexibility

It can process virtually any electrically conductive material, including:

- Hardened tool steels

- Carbides

- Titanium alloys

- Inconel

- Aluminum and copper alloys

- Tungsten

Industries That Rely on wire edm production services

The applications of wire edm production services span across a wide variety of industries that rely on ultra-precise components.

🚀 Aerospace

In aerospace engineering, tolerance is everything. Wire EDM is used for manufacturing engine components, airframe parts, and turbine blades from exotic and heat-resistant materials.

🏥 Medical Devices

Medical device manufacturers leverage wire EDM to produce complex implants, surgical tools, and orthopedic parts with smooth finishes and biocompatible materials like titanium.

🚗 Automotive

From transmission gears to injector nozzles and brake system components, the automotive industry utilizes wire edm production services to achieve repeatability and cost-effectiveness in mass production.

🔧 Tool & Die Making

Wire EDM is invaluable in the production of dies, molds, punches, and tooling. Its ability to machine hardened steels with fine detail is unmatched.

📱 Electronics

Micro-EDM versions of wire EDM are used to create miniature components used in semiconductors, sensors, and micro-connectors.

The wire edm production Workflow

The process behind wire edm production services typically follows these steps:

- Design & CAD Modeling

Clients provide 2D drawings or 3D CAD models that outline dimensions and material requirements. - Programming the EDM Machine

CAM software converts CAD designs into machine-readable instructions, optimizing path strategies for efficient cutting. - Workpiece Preparation

The conductive workpiece is mounted on the EDM machine. Tensioned wire (usually brass) is threaded and aligned for cutting. - EDM Process Begins

A dielectric fluid surrounds the cutting area as the wire electrode delivers sparks that erode material and follow the programmed path. - Post-Processing & Inspection

After cutting, components are cleaned, deburred (if needed), and undergo inspection using precision measuring equipment like CMMs or vision systems.

Benefits of Outsourcing wire edm production services

✅ Access to High-End Technology

Wire EDM machines are capital-intensive. Outsourcing allows companies to leverage state-of-the-art equipment without investing in new infrastructure.

✅ Reduced Lead Time

Dedicated EDM service providers operate with optimized workflows, enabling faster turnaround times even for complex jobs.

✅ Cost Efficiency

Lower tooling costs and minimized material waste make wire EDM an economical option for prototyping and small-to-medium production runs.

✅ Skilled Technicians

Experienced operators and engineers are familiar with the complexities of EDM programming, setup, and material handling.

✅ Quality Assurance

Many wire edm production services are ISO-certified and follow strict inspection protocols to ensure component accuracy and consistency.

Considerations When Choosing wire edm production services

Before selecting a service provider, assess the following:

- Experience & Portfolio: Look for companies with experience in your specific industry or material requirements.

- Certifications: ISO 9001, AS9100 (aerospace), or ISO 13485 (medical) certifications indicate commitment to quality.

- Equipment Capabilities: Ensure they operate multi-axis, CNC-controlled EDM machines capable of handling the desired material and part complexity.

- Quality Control Measures: Ask about in-process inspections, post-machining measurement tools (like CMMs), and documentation provided.

- Communication & Support: Opt for providers who are responsive, collaborative, and capable of providing design feedback or engineering support.

The Future of wire edm production services

As technology continues to evolve, wire edm production services are expected to become even more sophisticated:

- Integration with Industry 4.0: EDM machines equipped with sensors and data analytics tools for predictive maintenance and real-time optimization.

- Micro-EDM Advancements: Shrinking wire diameters and improved accuracy will allow for machining even smaller, more delicate components.

- Eco-Friendly Innovations: Use of biodegradable dielectric fluids and energy-efficient machinery will reduce environmental impact.

- Automation & Robotics: Full-scale robotic loading/unloading systems for “lights out” manufacturing environments.

Conclusion

In a market driven by precision, complexity, and rapid innovation, wire edm production services have become an indispensable part of modern manufacturing. They empower companies to design and produce components with unparalleled accuracy, surface quality, and geometric complexity.

Whether you’re building aerospace components, surgical tools, automotive parts, or micro-electronics, partnering with a reliable EDM production service can streamline your workflow, reduce overhead, and ensure product excellence. As this technology continues to grow and evolve, it will remain a cornerstone of advanced manufacturing for decades to come.