concrete pumps: From Innovation to Industry Standard

The construction industry has always been shaped by technology and innovation. Among the most transformative machines in the field is the concrete pump—a tool that has not only changed how concrete is delivered but also improved the efficiency, precision, and safety of modern construction. What once began as a simple solution to a complex labor problem has now evolved into a cornerstone of high-tech building practices.

Today, concrete pumps are used across the globe, from massive infrastructure projects and high-rise developments to small residential jobs. Their journey, however, is a story of continuous improvement, driven by engineering needs and environmental concerns.

The invention of concrete pumps

Before its invention, concrete was poured using buckets, wheelbarrows, or hoists—a time-consuming and labor-intensive process that was prone to error and material waste.

The early versions of concrete pumps were piston-driven systems that offered a mechanical solution to manually transporting wet concrete. Though primitive by today’s standards, these early machines marked the beginning of a revolution that would shape construction techniques for the next century.

Evolution and milestones

Over the decades, concrete pumps have undergone massive transformations. Key milestones include:

- 1950s–60s: Introduction of truck-mounted pumps allowed for greater mobility and job site flexibility.

- 1970s: Emergence of boom pumps with hydraulic arms enabled vertical pumping, crucial for high-rise construction.

- 1990s: Improvements in materials and pressure control systems increased pump efficiency and durability.

- 2000s–Present: Introduction of digital control systems, GPS tracking, and eco-friendly electric pumps have enhanced safety, precision, and sustainability.

The evolution of concrete pumps reflects not just a technological journey but also a response to changing construction needs and global environmental awareness.

See also: Hiring a SEO Freelancer: Costs, Benefits & Business Growth

Types of modern concrete pumps

The modern market offers a range of concrete pumps, each designed for specific applications:

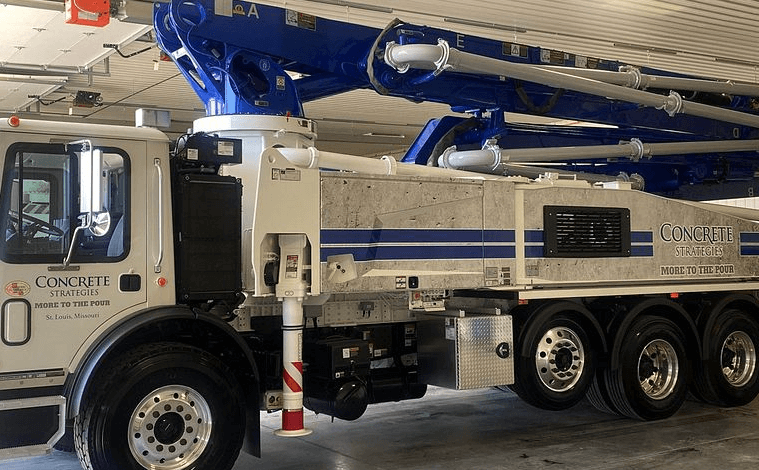

1. Boom Pumps

3. Specialized Pumps

There are custom-built concrete pumps used in tunnels, mines, or for shotcrete applications. These are tailored to specific job requirements where standard machines may not be suitable.

How concrete pumps have transformed construction

The introduction and adoption of concrete pumps brought about a host of benefits that reshaped how construction projects are executed:

– Speed and Productivity

Concrete can be placed directly and continuously at the exact location, reducing downtime and increasing daily output.

– Labor Efficiency

With fewer manual tasks involved, teams can work more efficiently with smaller crews—helping mitigate labor shortages.

– Improved Safety

Pumping minimizes the need for workers to carry heavy materials or operate around hazardous equipment zones.

– Cost Savings

Though pumps involve upfront costs (either purchase or rental), they significantly reduce labor costs, material wastage, and construction delays.

concrete pumps in sustainable construction

As sustainability becomes a global priority, concrete pumps have proven to be an eco-conscious choice in the construction sector. Here’s how:

1. Reduced Material Waste

Accurate placement of concrete minimizes spillage and unnecessary mixing, which reduces cement consumption—a major contributor to carbon emissions.

2. Lower Emissions

Newer pump models are equipped with low-emission engines or are fully electric, suitable for urban builds or enclosed environments.

3. Energy Efficiency

Modern control systems ensure optimized pumping power, using only as much energy as needed for the task.

4. Cleaner Sites

Less manual transport means cleaner job sites, less dust, and reduced environmental contamination.

Industry applications: Where concrete pumps shine

concrete pumps are now used across virtually every sector in the construction industry. Some notable applications include:

- High-rise Construction: Vertical pumping over 100 meters made possible by advanced boom pumps.

- Infrastructure Development: Roadways, overpasses, tunnels, and dams benefit from precise placement over large areas.

- Residential Projects: Foundations, walls, patios, and floors—completed faster and cleaner with line pumps.

- Industrial Sites: Factories and warehouses require durable concrete floors and large volumes—perfect for high-output pumps.

- Remote Locations: Where trucks can’t go, pumps with extended hoses ensure concrete reaches the desired point.

The future of concrete pumping

As construction continues to evolve, so will the role of concrete pumps Emerging trends include:

- Smart Fleet Management: Centralized tracking and control of pump fleets via cloud platforms.

- Modular Pump Designs: Easier maintenance and transport, especially for small contractors.

- Integration with BIM (Building Information Modeling): Ensuring concrete pours align with digital blueprints in real time.

These advances are expected to push the industry toward higher precision, faster delivery, and greener construction practices.

Conclusion

From their humble beginnings nearly a century ago to their high-tech versions of today, concrete pumps have redefined what’s possible in construction. More than just machines, they represent progress—combining speed, safety, and sustainability in one package.

For contractors, developers, and engineers, understanding the value and capabilities of concrete pumps is no longer optional—it’s essential. As project timelines shrink and environmental regulations tighten, only those who adopt modern tools like these will stay ahead in the competitive construction landscape.

Whether you’re working on a skyscraper in a bustling city or a foundation in a quiet suburb, concrete pumps offer the power to build better, faster, and smarter.