How Industrial Automation Relies on Efficient Stator Winding

In today’s era of smart factories and high-precision manufacturing, industrial automation is no longer a luxury—it’s a necessity. Central to this shift is the electric motor, the workhorse behind countless machines, tools, and production systems. At the core of every motor lies a critical component: the stator. The performance of the motor—and by extension, the entire automated system—depends significantly on the quality and efficiency of stator winding. This is where innovations like the motor stator winding machine and segmented stator winding come into play.

The Role of Stator Winding in Industrial Automation

The Heart of the Motor

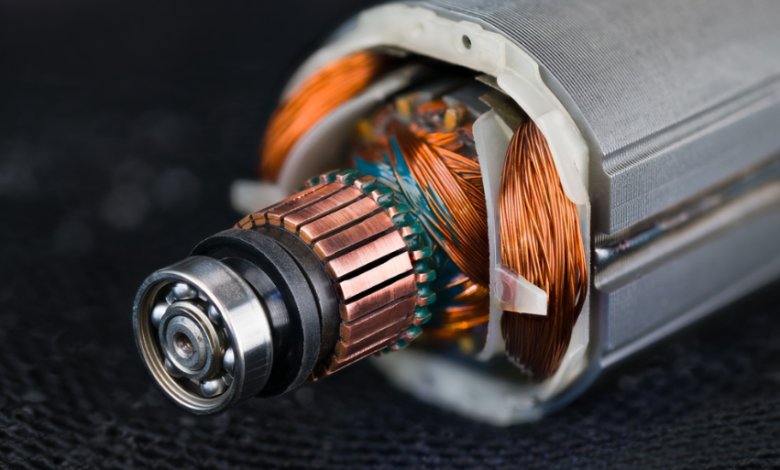

The stator is the stationary part of an electric motor, comprising a core and windings. These windings generate the magnetic field needed to induce motion in the rotor, which results in mechanical energy. Efficient stator winding ensures optimal magnetic flux, leading to smooth motor operation, better torque, and improved energy efficiency—all essential for automation systems that require precision and reliability.

See also: Advanced Graphics Technology Powers Sweet Bonanza’s Vibrant Visual Effects

Precision and Consistency

In industrial automation, even minor inconsistencies can cause costly delays or quality defects. A motor with poorly wound stators can generate excess heat, consume more energy, or fail prematurely. Efficient winding practices eliminate such risks by maintaining uniformity in wire tension, placement, and insulation. This is especially crucial in automated systems where downtime equates to significant losses.

Motor Stator Winding Machines: The Backbone of Precision Winding

Advancements in Winding Technology

Modern motor stator winding machines are engineered to deliver high-speed, precise, and consistent coil winding. These machines have largely replaced manual winding, which is time-consuming and prone to errors. Automated winding systems ensure consistent quality, reduce labor costs, and increase production rates—factors that are vital for keeping up with the demands of industrial automation.

Benefits for Manufacturers

- High Productivity: These machines can wind multiple stators simultaneously, dramatically improving throughput.

- Reduced Human Error: Automation in winding reduces inconsistencies caused by manual processes.

- Scalability: Easily adaptable to different motor sizes and specifications, allowing manufacturers to meet a wide range of industry needs.

By integrating motor stator winding machines into their production lines, manufacturers can ensure motors are built to meet the exacting standards of today’s automated industries.

Segmented Stator Winding: A Game-Changer for Efficiency

What is Segmented Stator Winding?

Traditional winding methods involve inserting coils into a full circular stator core, which can be difficult and limit design flexibility. Segmented stator winding, on the other hand, involves winding individual stator segments separately before assembling them into a full stator. This technique simplifies the manufacturing process and enhances winding quality.

Advantages in Automation

- Improved Heat Dissipation: Segmented designs offer better thermal performance, increasing motor longevity.

- Higher Winding Density: Enables tighter and more uniform coil placement, improving motor efficiency.

- Faster Assembly: Winding segments individually allows for parallel processing, significantly reducing production time.

- Design Flexibility: Supports compact motor designs, ideal for space-constrained automation systems.

These advantages make segmented stator winding an increasingly popular choice in motors used for robotics, conveyor systems, and CNC machinery—all staples in automated industries.

Efficiency Gains Across the Automation Spectrum

Energy Savings

Efficient winding reduces electrical resistance and enhances magnetic efficiency, translating into lower energy consumption. This is a critical factor in industrial automation, where multiple motors run simultaneously and energy costs can be substantial.

Enhanced Motor Performance

High-quality winding improves torque output and dynamic response, both of which are essential for applications like robotic arms or high-speed sorting lines. Motors with optimized stator winding can maintain precise speed and position control, ensuring automation systems operate at peak performance.

Extended Motor Life

Better heat management and reduced vibration from precision winding extend motor lifespan, minimizing the need for maintenance and replacement. This reliability is vital in automated environments that depend on continuous, uninterrupted operation.

Integration with Smart Manufacturing

Data-Driven Winding Processes

Modern motor stator winding machines are often equipped with sensors and software that collect data on winding tension, insulation resistance, and alignment. This data can be fed into a central system for real-time quality control, predictive maintenance, and process optimization—key aspects of Industry 4.0.

Compatibility with Modular Automation

Segmented stator winding supports modular motor designs that align well with modular automation systems. This synergy simplifies repairs, upgrades, and customization, allowing facilities to adapt quickly to new production demands.

Future Trends in Stator Winding for Automation

As automation continues to evolve, so will the technologies surrounding motor manufacturing. We can expect:

- Increased use of AI in monitoring and controlling winding quality.

- Advanced materials for windings and insulation to support higher power densities.

- More compact winding machines designed for flexible, decentralized production cells.

- Wider adoption of segmented winding in medium and large motors, not just compact models.

These developments will further enhance the role of stator winding in achieving faster, more reliable, and energy-efficient industrial automation.

Conclusion

Efficient stator winding is no longer just a technical detail—it’s a cornerstone of modern industrial automation. From motor stator winding machines that ensure consistency and scalability to segmented stator winding that offers design flexibility and performance gains, these innovations are driving the evolution of smarter, more efficient factories. As the demand for precision, reliability, and speed in automation grows, so too will the importance of mastering the art and science of stator winding.